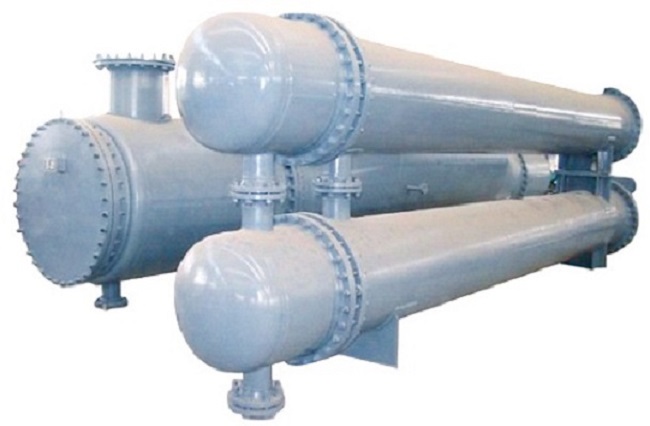

Condensers Cold-drawn precision single welded steel tubes

Product Description

water-cooled condenser types

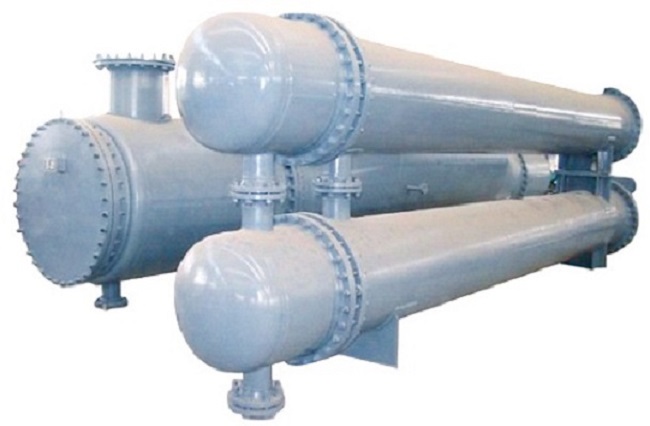

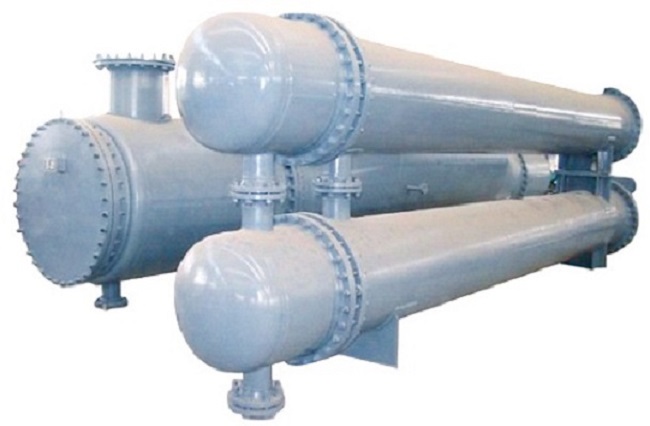

Commercial water-cooled condensers are of three basic types:

- Shell and coil water-cooled condenser: the shell condenser is a steel tank enclosing copper tubes inserted in the shell. As water flows through the tubing, it condenses hot gases into a fluid and the bottom part of the shell receives the fluid. The benefits of this type of separate condensers include compact design and elimination of fans. Since the coils are completely surrounded by a steel shell, the mechanical cleaning of such coils is almost impossible.

- Tube within a tube (double-tube) water-cooled condenser: the second type of these condensers is double-tube. One tube is put within another one in a way that water flowing through the inside tube cools the refrigerant in the outside tube. The construction of this condenser can be either in the cylindrical spiral or in the rectangular style.

- Shell and tube water-cooled condenser: shell and tube is the most common type of such condensers in chemical processing plants which consists of number of straight water tubes enclosed by a large cylindrical shell. Tube diameters of 15mm to 50mm are common, while the number of tubes in the condenser varies from as few as six or eight to as many as one thousand or more. The end-plates of the condenser are removable to allow mechanical cleaning of the water tubes.

-

Advantages of a Water-Cooled Condenser

- Where there is restriction for air-cooled condenser, water-cooled condenser is a perfect replacement.

- There is thermal energy recovery to be used in other heating processes.

- This type of condenser can be housed indoors.

- A water-cooled system typically lasts years longer, assuming maintenance is not neglected.

- It has higher heat transfer rate.

- It consumes far less overall energy, which can lead to savings on energy costs and consumption.

- It does not require any external power.

- Since water cooling is more efficient than air cooling, time required for cooling is less.

- Length of the condenser pipe is reduced which decreases the compressor work and thus increases its efficiency.

- With the incorporation of these condensers, the net weight of the system increases.

Disadvantages of a Water-Cooled Condenser

- Using water as a cooling medium might cause corrosion problem.

- Use of water as a cooling medium may result in the formation of scales in the supply line.

- Because of shortages of fresh water around the world, few countries can afford to run water to waste.

- Using water tank makes the system bulky which results in problem during domestic use.

-

Product Categories : Condensers > Water-Cooled Condenser

Hot Products

Manufacturer supply aluminum bend tube 90 degree metal tube bend stainless steelSST helical coil type heat exchanger,stainless steel heat exchanger coilSST tube immersion stainless steel coil heat exchanger for water tank heatingAir conditioner and water heaterGood quality empty steel drumNew products solar energy system buffer tank 1000lIndirect thermosiphon solar water heater50L-1000L high quality home solar system 6kwSST back-up water heater for heat pump water heater ,backup heaterAutomatic welding machine stainless steel pressure water tank 200lISO9001 certified good quality waterproof water tank insulationDomestic hot water heat pump 3.5kw with square water storage tank 180l100L-500L high quality easy instant electric water heater,electrical water heaterLong life span stainless steel storage tank,stainless steel hot water storage tank300L duplex stainless steel mini boiler,electrical water boilerSST watermark certified flexible price insulated stainless steeL solar hot water storage tank , electric/buffer tank for boiler